Steel wire ropes are essential components in a vast array of industries, from construction and mining to marine and elevators. Their ability to support heavy loads, withstand repetitive stress, and offer great tensile strength makes them indispensable. The manufacturing of these robust products is a complex and precise multi-stage process that transforms raw steel into highly reliable, engineered assemblies. This process typically involves preparing the raw material, drawing the wire, forming strands, laying the strands into a rope, and finally, applying finishes and conducting rigorous quality assurance.

🔩 Stage 1: Raw Material Selection and Preparation

The journey of a steel wire rope begins with the selection of high-quality steel rods, which serve as the fundamental raw material.

High-Carbon Steel: The Backbone

The primary material used is typically high-carbon steel, often with a carbon content ranging from $0.4\%$ to $0.95\%$. This specific steel composition is chosen for its superior tensile strength and durability, which are crucial for heavy-duty, high-load applications.

-

Other Materials: Depending on the intended application, stainless steel (for corrosion resistance in marine or wet environments) or various alloy steels (for enhanced fatigue resistance or specific performance characteristics) may be used.

-

Initial Rod Treatment: The raw steel rods, produced through a hot-roll process, must first be prepared for the subsequent drawing phase. This preparation involves surface treatment, such as pickling (to remove rust and scale) and sometimes phosphating or oiling, to clean the surface and facilitate the drawing process.

📏 Stage 2: Wire Drawing and Heat Treatment

The prepared steel rods are far too thick for direct use in a rope. The next crucial step is wire drawing, a cold-working process that significantly reduces the rod’s diameter while enhancing its mechanical properties.

Wire Drawing: Increasing Strength

The rod is pulled through a series of progressively smaller drawing dies at room temperature.

-

Diameter Reduction: This process reduces the wire’s cross-section to the precise, uniform diameter required for the final rope construction.

-

Work Hardening and Strength: Wire drawing is classified as a cold-working process, and as the steel is drawn, it undergoes work hardening. This process drastically increases the wire’s tensile strength—its ability to withstand immense pressure without snapping—a key characteristic of the finished rope.

-

Uniformity: Maintaining extreme uniformity in the wire’s diameter is vital, as any variation can create weak points in the final rope.

Heat Treatment (Patenting and Tempering)

The intense cold working during drawing can induce internal stresses in the steel wire, making it brittle. To restore ductility and prepare it for further drawing and eventual twisting, a heat treatment process is often applied.

-

Patenting: This is a specific heat treatment, involving heating the wire to a high temperature (austenitizing) and then holding it at a lower temperature (isothermal quenching). This transforms the microstructure of the steel into a fine pearlitic state, which is ideal for subsequent drawing and rope-making.

-

Tempering/Annealing: These processes balance the wire’s hardness with its flexibility (ductility), allowing the wire to bend without breaking under repetitive stress cycles, which is critical for a functional rope.

⛓️ Stage 3: Stranding

The individual steel wires, now possessing the required diameter and mechanical properties, are brought together to form strands.

Forming the Strand

A strand is a compact assembly of multiple wires, typically laid helically around a central wire or strand core. This process is carried out using a specialized industrial machine called a strander.

-

Lay Patterns: The way the wires are laid together determines the strand’s characteristics. Common patterns include:

-

Cross Lay: Wires in different layers cross each other. This is less common.

-

Parallel Lay: Wires in superimposed layers lie parallel to each other, resulting in linear contact. Parallel lay strands (such as Seale, Warrington, or Filler) offer much greater endurance and wear resistance.

-

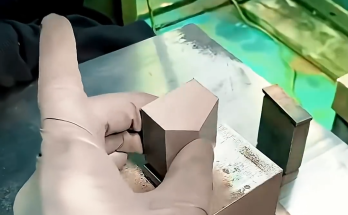

Compacting and Compression

To enhance the strand’s performance, it may undergo compaction. This process involves passing the strand through dies or rollers to achieve a denser, more uniform cross-section. Compaction maintains the steel area while increasing the fill factor (the ratio of steel to the strand’s total cross-sectional area), resulting in higher strength and improved resistance to crushing and abrasion.

🕸️ Stage 4: Closing (Rope Formation)

The completed strands are now ready to be assembled around a central support element to form the final steel wire rope in a process called closing or roping, performed on a rope-forming machine.

The Core: Support and Structure

The strands are twisted around a central core, which serves to support the strands and help the rope maintain its shape, especially under load. Cores are classified as:

-

Fibre Core (FC): Made of natural or man-made fibres (like polypropylene). Offers greater flexibility but less support and heat resistance.

-

Wire Strand Core (WSC): A single, separate strand that is structurally similar to the rope’s strands. Offers better support and heat resistance than FC.

-

Independent Wire Rope Core (IWRC): A complete, smaller steel wire rope unto itself, used as the main rope’s core. This provides the best support, heat resistance, and structural stability, often leading to longer rope life.

Rope Lay: Direction and Type

The final lay of the strands around the core is crucial for the rope’s performance and is defined by the lay direction of the wires in the strand relative to the lay direction of the strands in the rope.

-

Ordinary (Regular) Lay: The direction of the lay of the wires in the strands is opposite to the direction of lay of the strands in the rope. This is the most common lay, offering good resistance to kinking and untwisting.

-

Lang’s Lay: The direction of the lay of the wires in the strands is the same as the direction of lay of the strands in the rope. This offers better wearing surface and can last longer but produces higher torque values and must be used where both ends of the rope are fixed.

Pre-Forming

To ensure that the strands and wires sit tightly in their final helical position and reduce internal stress, a pre-forming operation is carried out before the final closing. This gives the strands their permanent helical shape, making the rope stable and less prone to unraveling when cut.

🛡️ Stage 5: Finishing and Quality Assurance

The finished wire rope undergoes final treatments to enhance its longevity and must pass stringent testing before being packaged.

Lubrication and Coating

To protect the rope from environmental factors and internal friction, it is lubricated and sometimes coated.

-

Lubrication: Special grease or lubricant is applied to the core and strands during the closing process. This reduces friction between the wires and strands as the rope bends and flexes, which is the main cause of fatigue failure. It also provides essential corrosion protection.

-

Coating (Galvanization): For applications exposed to moisture or harsh chemicals, the individual wires may be galvanized (coated with zinc) prior to stranding to provide an external barrier against rust and corrosion.

Quality Testing and Packaging

The final stage is critical to ensure the safety and reliability of the product.

-

Testing: Ropes are subjected to rigorous tests, including tensile strength tests (to determine the ultimate breaking force), bend tests, and fatigue tests, to ensure they meet the specific safety standards and specifications (e.g., ISO, EN).

-

Packaging: Once quality assured, the wire rope is cut to the required lengths, coiled, and wound onto wooden or steel reels (spools) for protected transport and delivery.

The production of steel wire ropes is an intricate fusion of metallurgy, mechanical engineering, and precise manufacturing processes, resulting in the high-strength, durable cables that literally hold much of modern industry together.